EN/DIN Mirija ya Chuma Inayong'aa yenye Baridi Inayotolewa kwa Usahihi

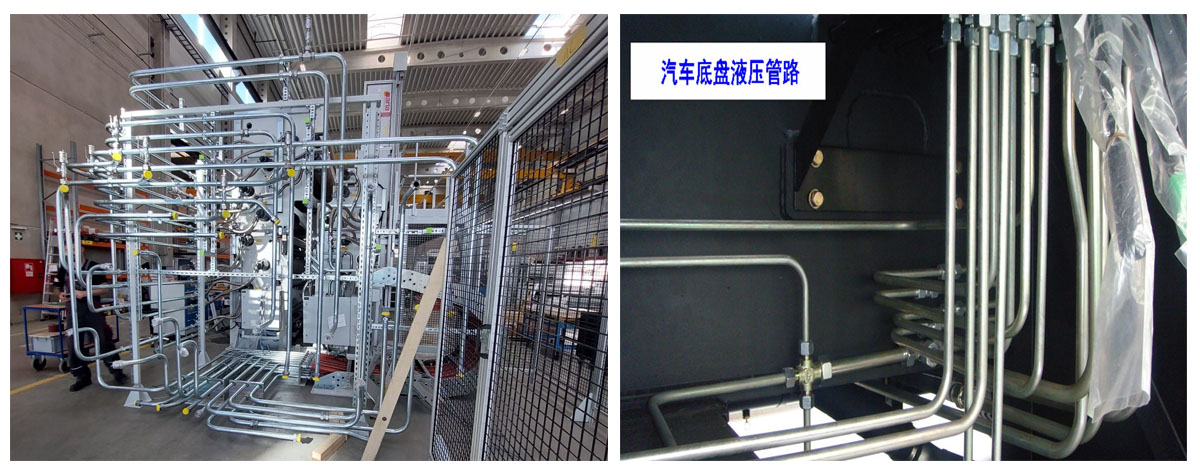

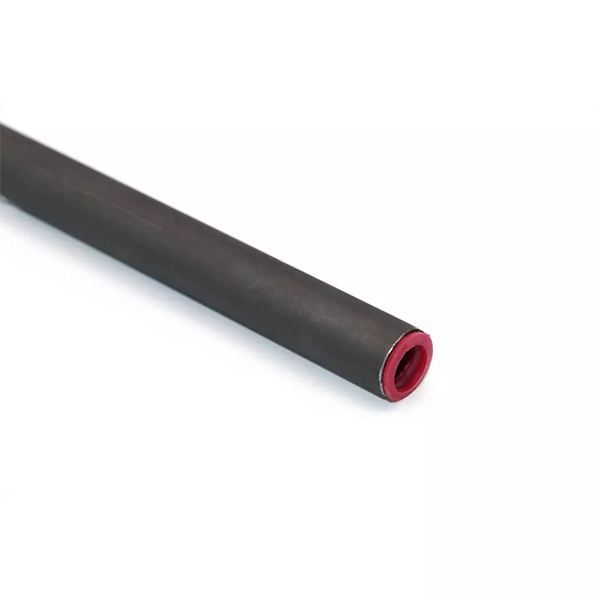

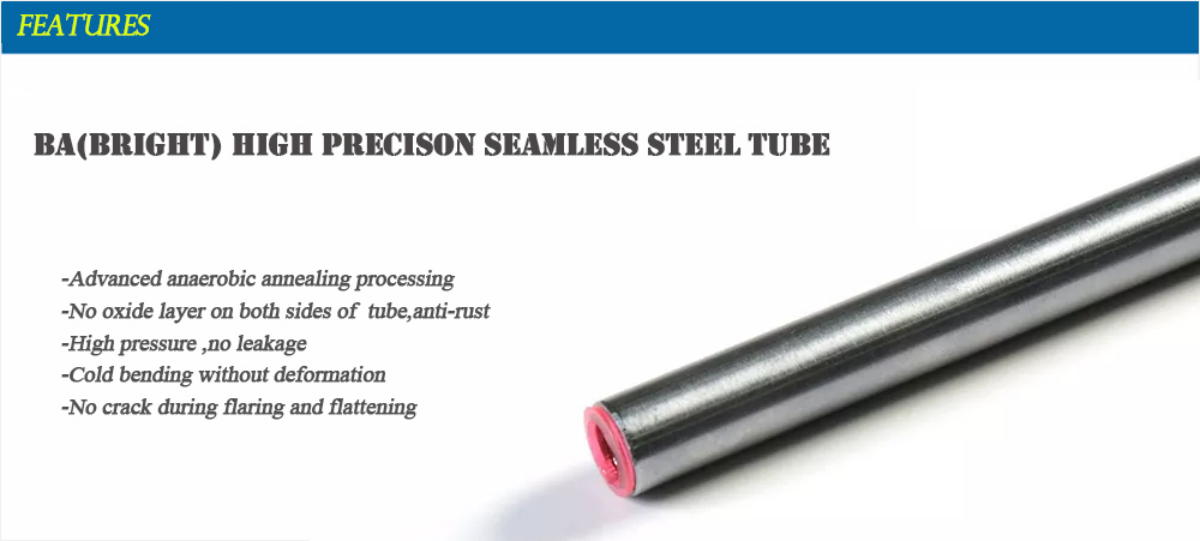

Bomba linaweza kupinda, kuwaka na kujaa bila ufa.Ina usahihi wa juu, kwenye safu ya oksidi pande zote mbili za tube.Inaweza kutumika kwa deformation tata mbalimbali na machining.Mrija wa chuma usio na mshono wa BA high precision hutumiwa kwa silinda ya hydraulic, dizeli, kituo cha pampu ya majimaji na mfumo wa majimaji ambayo yanahitaji bomba la chuma kwa usahihi wa hali ya juu na usafi.

Vipimo

| Kawaida | DIN2391 DIN1630 EN10305 DIN2445 JIS G3445 SAE J524 |

| Daraja | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Hali ya Uwasilishaji | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Ukubwa | OD:4 hadi 219mm Unene 0.5-35mm, Urefu: 3m, 5.8,6 au kulingana na mahitaji |

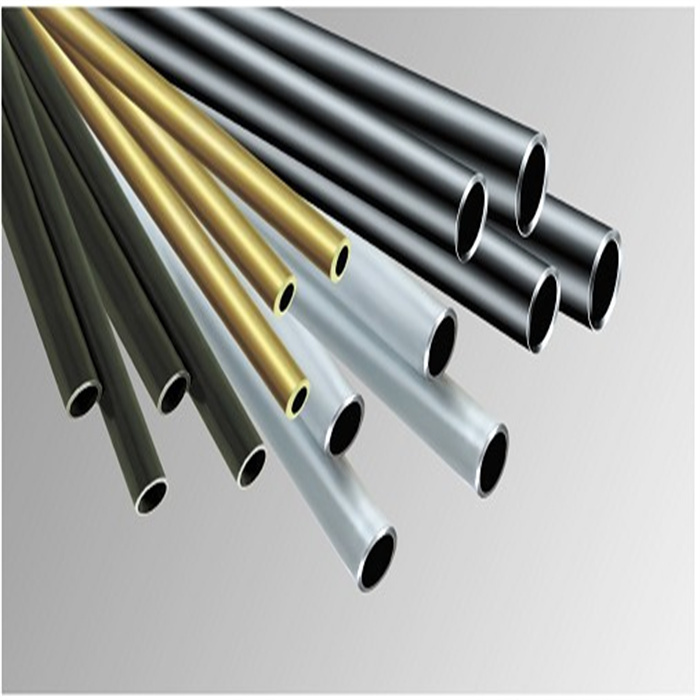

| Maliza | Uso wa mabati (Sliver/Njano/Rangi) Mipako ya zinki ya 8-12um |

| Maombi | Mfumo wa Hydraulic;Gari/basi;gari la ujenzi |

| Wakati wa utoaji | Siku A.3 ikiwa bidhaa hii ni ya hisa.B. Takriban siku 30 kulingana na wingi |

| MIRIJA YA CHUMA YA HYDRAULIC PRECISION KATIKA HIFADHI | ||||||||||

| OD | Unene(mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Kumbuka: Tunaweza kutoa saizi zingine kama mahitaji yako. Matibabu ya uso: Bright, Galvanized, Phosphated nk. | ||||||||||

Muundo wa kemikali

| Daraja la chuma | C | Si | Mn | P | S | Al | |

| Jina | Hapana. | max | max | max | max | max | max |

| E215 | 1.0212 | 0.1 | 0.05 | 0.7 | 0.025 | 0.015 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.025 | 0.015 | - |

| E355 | 1.058 | 0.22 | 0.55 | 1.6 | 0.025 | 0.015 | - |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4 (dakika) | 0.025 | 0.025 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4 (dakika) | 0.025 | 0.025 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.025 | 0.025 | - |

Mali ya mitambo

| Daraja la chuma | Nguvu ya Mazao (Mpa) | Nguvu ya Mkazo (Mpa) | Kurefusha (%) | |

| Jina | Hapana. | ReH (dakika) | Rm(dakika) | A(dakika) |

| E215 | 1.0212 | 215 | 290 hadi 430 | 30 |

| E235 | 1.0308 | 235 | 340 hadi 480 | 25 |

| E355 | 1.058 | 355 | 490 hadi 630 | 22 |

| ST35 | 1.0308 | 235 | 340 hadi 480 | 25 |

| ST45 | 1.0408 | 255 | 440 hadi 570 | 21 |

| ST52 | 1.058 | 355 | 490 hadi 630 | 22 |

Uvumilivu

| OD | Uvumilivu unaoruhusiwa | Uvumilivu Maalum | ||

| GB/T3639 | DIN2391 | OD | WT | |

| 4 mm-20 mm | ± 0.10mm | ±0.08mm | ± 0.05mm | ± 0.05mm |

| 20-30 mm | ± 0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31 mm-40 mm | ± 0.15mm | ± 0.15mm | ± 0.10mm | ±0.08mm |

| 41-60 mm | ± 0.20mm | ± 0.20mm | ± 0.15mm | ± 0.15mm |

| 61mm-80mm | ± 0.30mm | ± 0.30mm | ± 0.20mm | ± 0.20mm |

| 81mm-120mm | ± 0.45mm | ± 0.45mm | ± 0.30mm | ± 0.30mm |

Hali ya utoaji

| Uteuzi | Alama | Maelezo |

| Baridi imekamilika (ngumu) | BK(+C) | Mirija haifanyi matibabu ya joto kufuatia uundaji wa baridi ya mwisho na, kwa hivyo, ina upinzani wa juu kwa deformation |

| Baridi imekamilika (Laini) | BKW | Matibabu ya mwisho ya joto hufuatiwa na kuchora baridi inayohusisha deformation ndogo.Usindikaji zaidi unaofaa huruhusu kiwango fulani cha uundaji wa baridi (kwa mfano. kupinda, kupanua) |

| (+LC) | ||

| Baridi imekamilika na kupunguza mkazo | BKS(+SR) | Matibabu ya joto hutumiwa kufuatia mchakato wa mwisho wa kuunda baridi.Kwa kuzingatia hali zinazofaa za usindikaji, ongezeko la mikazo ya mabaki inayohusika huwezesha kuunda na kutengeneza kwa kiwango fulani. |

| Annealed | GBK(+A) | Mchakato wa mwisho wa kuunda Baridi hufuatwa na kuingizwa kwenye angahewa iliyodhibitiwa. |

| Imesawazishwa | NBK(+N) | Mchakato wa mwisho wa uundaji wa baridi hufuatwa na kuingizwa juu ya sehemu ya juu ya mabadiliko katika anga inayodhibitiwa. |

Ubora

1.Madhubuti kulingana na DIN2391/EN10305 au viwango vingine.

2. Sampuli: Sampuli ni bure kwa majaribio.

3. Vipimo: Mtihani wa dawa ya chumvi/Mtihani wa Kupunguza nguvu / Mtihani wa sasa wa Eddy / Mtihani wa muundo wa kemikali kulingana na ombi la wateja

4.Cheti: IATF16949, ISO9001, SGS nk.

5.EN 10204 3.1 Uthibitisho

Maombi